A better way

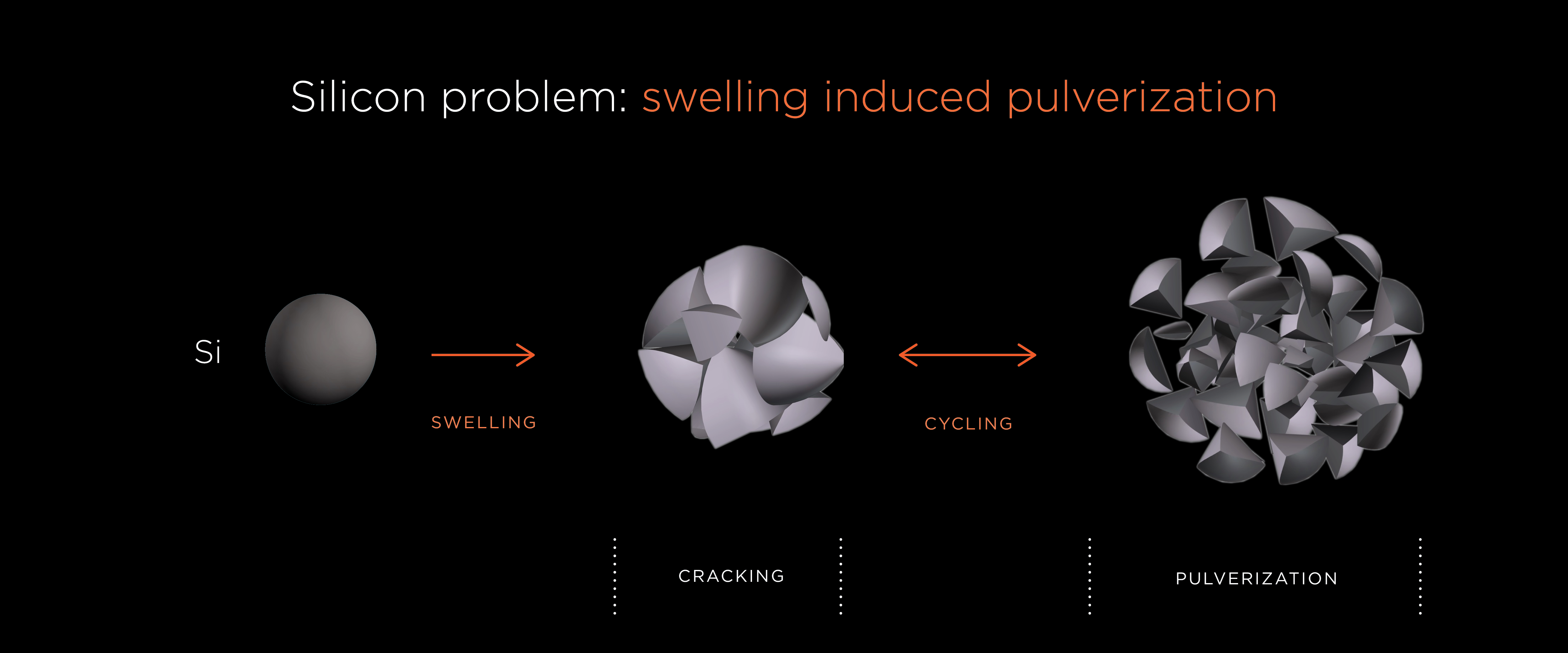

Silicon is abundant, environmentally-friendly to mine and can hold 10 times the capacity of graphite. Yet when it absorbs lithium, silicon expands over 300%, and quickly fractures.

Current thinking about how to solve this problem relies on expensive and exotic processes. We asked if there was a better way—high performance and low cost?

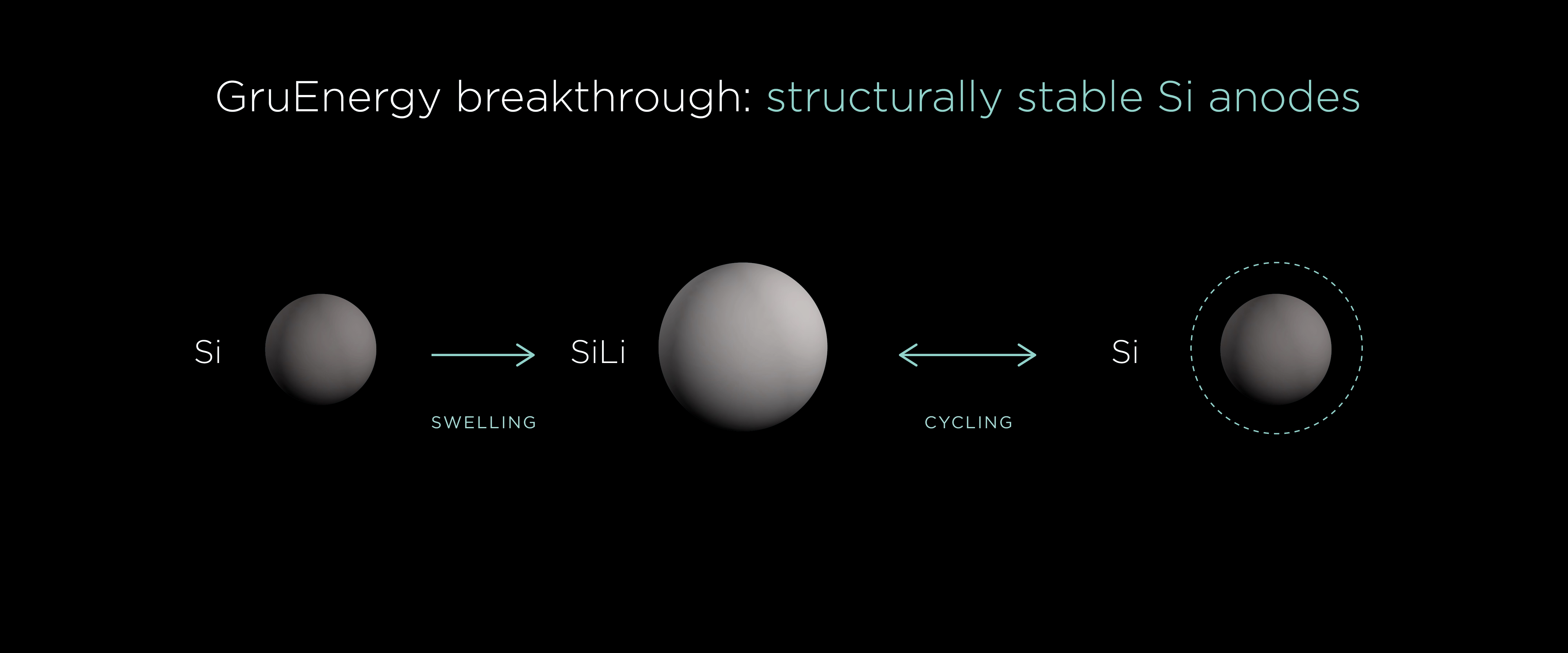

GruEnergy’s innovation uses cost-efficient and environmental-friendly processes to produce silicon without fracturing during charging/discharging. These breakthroughs are revolutionizing charging time and opening the gateway to higher energy density than ever before.

Culture of innovation

Battery technology today won’t get us where we need to go.

Disruptive innovation is needed to dramatically advance energy density and fast charging material performance. Our material innovations give battery makers the opportunity to greatly improve battery performance today.

Our creativity on the leading edge of science is shaping the future-ready solutions for tomorrow.

Tested, proven and delivered

All users of lithium-ion batteries are looking for fast charge time, high energy density and long cycle Life. GruEnergy’s Si/C composite anode, available in volume production today, provides all of these benefits in a cost effective solution, opening the way for near universal electrification.

Drop in, low cost solution

Our silicon anode material in commercial production today drops into existing cell manufacturing processes, avoiding large capital and engineering outlays. There is no need to change the battery architecture, fabrication, or assembly processes.

Our innovative silicon anode material is key to higher energy density. Capacity improvements reduce battery size, weight, and cost and save on costly materials such as nickel, cobalt, and lithium.

Our 92% First Cycle Efficiency means no expensive pre-lithiation is required.

United States

San Jose,

California

- Global Headquarters

- Research & Development Center

- Prototype Si anodes

- Prototype battery cells

Asia

Changzhou,

Jiangsu Province, China

- Regional Headquarters

- Production Facility and Customer Fulfillment

- Product Application Support and Analysis